Fuski BOMA s.r.o. socks production.

-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-

How are socks made? By knitting.

And to be wearable, they must not be knitted by a muddler, but by a professional who knows how to do it!

-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-

At the very beginning there is an idea that we have to be able to transfer and correctly place and distribute point by point into a square grid so that it somehow "looks" (The pattern placement on the sock is calculated based on size, colors and complexity - each dot equals one eyelet.) Patterning simple inscriptions takes several hours, while patterning complex images can take several days!

-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-

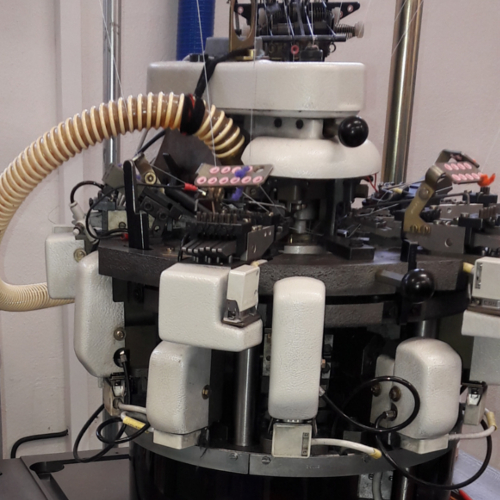

When the pattern is ready and the right colors and materials are chosen (and there are plenty to choose from, there are over 1500 colors alone),

An experienced knitter comes in and has to thread them into the knitting machine and set everything up and weave it so that at the end of the day the first sample falls out.

-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-

Phew, it's not over yet. The wrinkled, shapeless pattern is here, but now we're just seeing how our pattern looks on a sock. Not everything works on the first try. And then you have to adjust the pattern, colors, thread tension...

-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-

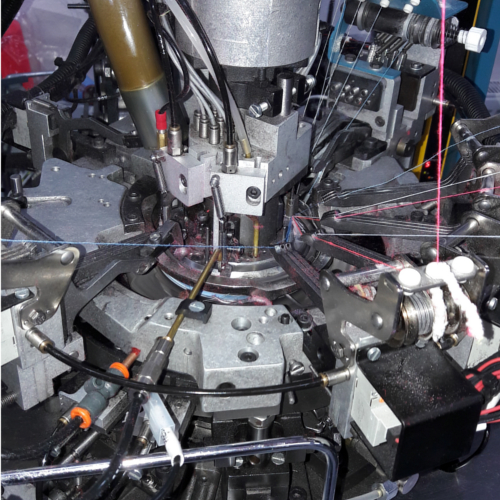

It worked, we can start knitting on a large scale! When production starts, the knitting process itself must be constantly monitored, sometimes the yarn breaks or falls out, other times it gets tangled up. The voltage must also be set correctly, otherwise it will be crap, and we really don't want that.

-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-

The sock blank is ready! The next step is to close the toe, which a knitting machine cannot do. To prevent the toes from "peeking" out of the sock, we close the toe on a special machine that closes the socks using a more demanding sewing technique called chaining. Thanks to it, the joint is perfectly smooth and there is no risk of the sock pressing. It is faster and a little easier to sew the edges on a Rosso sewing machine, which can make a fine seam.

-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-

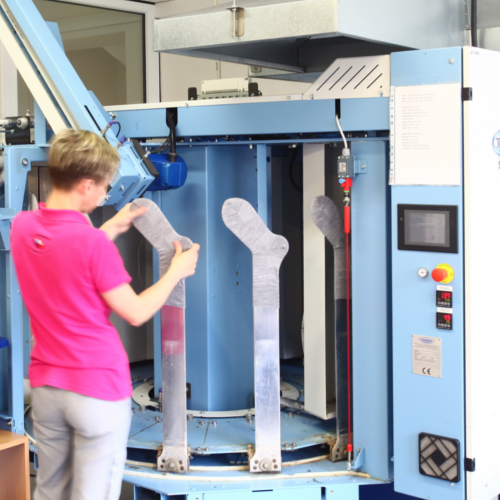

What next? Now comes the next process, which is steaming and ironing. This is how we achieve the final shape. We stretch each sock onto a special mold that passes through a steam and pressure chamber. At the end, we have a finished product, but the work is not over yet.

-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-

Ironed and we move on. Individual socks must be paired. It goes without saying that each sock will be the same size in the pair. At the same time, during pairing, each "original" undergoes an optical inspection. So we look/pair/look/pair/look/pair and we do it all day long...

-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-

In order to sell our socks, each pair or package must have a label or wrapper on which you can find all the important information. Of course, their name, size, what materials they are knitted from, what temperature they can be washed at and that they really don't need to be ironed. A barcode must also be included.

-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-

And it's done. Then all the socks come together in our central warehouse and from there they can go out into the world.